How to optimize your clinical trial manufacturing plan

Are you making the best possible decisions about your clinical trial manufacturing?

It can feel like an impossible task to optimize manufacturing throughout the entire process, but it is possible — and crucial, as manufacturing decisions impact all later stages of the clinical supply chain.

Streamlining clinical trial manufacturing will yield results like improved drug allocation to trials, more trials initiated simultaneously, and accelerated time to market — not to mention reduced drug waste and costs.

You don’t just want a feasible plan; you want the optimal plan. But how can you achieve it?

Streamline clinical trial material manufacturing

What does the optimal clinical trial manufacturing plan look like? First and foremost, it calls for the right quantities and timing for drug substance (DS) manufacturing, drug product (DP) manufacturing, and investigational medicinal product (IMP) manufacturing in order to get trials running as quickly and smoothly as possible with a minimum amount of drug waste.

But the optimal plan is also a flexible one. Unplanned protocol updates often occur, yield isn’t always as good as expected, so streamlining clinical trial manufacturing means being able to adapt to unexpected events as they come.

The N-SIDE Production App takes into account all the manufacturing constraints specific to your program and embeds safety margins to protect against uncertainties such as delays in production. It then helps CMC teams make data-driven decisions that streamline the clinical trial supplies manufacturing process, both during initial planning and while trials are ongoing.

The Production App supports you in making the best initial decisions about:

-

DS/DP/IMP batch sizes, number of batches and timing

-

Manufacturing network design

-

Vendor selection

-

Packaging strategy

-

Allocation to clinical trials

-

Outsourcing vs. in-house manufacturing

-

Budgeting

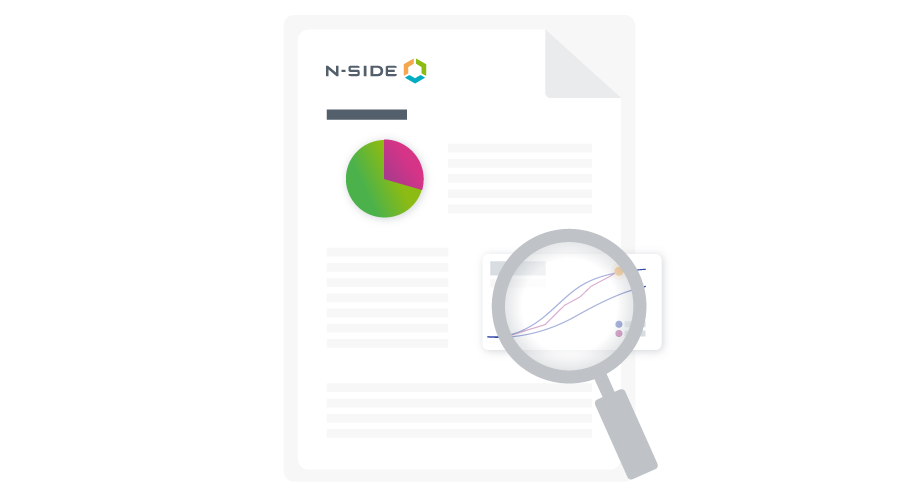

Allocation chart

Once you’ve created the most efficient initial plan, N-SIDE’s software helps you adapt to changes, including new trials; protocol amendments; updated recruitment forecasts; batch delays and losses; stability updates, etc.

How the N-SIDE Production App works

Powered by a state-of-the-art mathematical optimization algorithm, N-SIDE’s Production App combines complex inputs to power data-driven decision-making.

Inputs include:

- Stability plans and related shelf-life extensions

- Clinical, technical, and commercial needs

- Manufacturing and shipping lead times

- Bill of Materials

- Production capacity constraints

- Costs

- Current inventories

- Ongoing production runs

With the Production App, you can simulate “what if” scenarios to proactively test and model changes to clinical operations, then adapt quickly to whatever scenarios arise.

Learn more: Reduce the stress of clinical supply chain planning by taking the global view.

Optimize clinical batch manufacturing

Decisions about the size and timing of batches, or lots, have a massive downstream impact, so optimizing clinical batch manufacturing is pivotal. When you make the most efficient decisions about when to produce what quantities of DS, DP, and IMP, you can supply more patients and trials with the same production resources as fewer drugs end up being wasted.

Fixed lot sizing works in theory when you’re doing the analysis and simple optimization in a spreadsheet. However, due to the uncertainty of clinical trial demand, fixed lot sizing often leads to non-optimal production quantities.

The N-SIDE Production App helps you plan for clinical batch manufacturing with varying lot sizes, so you can scale with actual demand, resulting in major cost savings and reduced DS, DP, and IMP waste.

Learn more: Lot sizing in clinical trials manufacturing can save more than you think.

Enhance downstream collaboration and unlock true end-to-end visibility

The entire clinical supply chain is connected, and there are hundreds of decisions up and down the chain that have an impact on your manufacturing plan. But this data is not always readily available, it is usually siloed. The best way to maximize manufacturing efficiency is by improving collaboration.

With a global view of your manufacturing strategy, you’ll have accurate real-time data from your trials to make collaborative decisions.

The N-SIDE Production App is part of a larger platform, the N-SIDE solutions, which also includes the N-SIDE Supply App. The Supply App helps teams understand the demands of each trial to make the best decisions about supply, and provides real-time data that can be used to monitor, reevaluate, and optimize the supply strategy during every trial. Data integration through APIs provides a seamless experience. Used together, the Production and Supply Apps unlock a truly streamlined clinical trial manufacturing plan.

Contact N-SIDE to learn how the Production App can help streamline your clinical trial manufacturing plan:

About the Author

Antoine Remiot is N-SIDE's Director of Solutions Engineering. Over the past years, Antoine has been sharing his enthusiasm about lean clinical supply chain management, waste reduction, and sustainability with various pharma partners he supported in their change management journey towards digitalization. Antoine is passionate about leveraging data and AI to improve clinical supplies efficiency. He gained expertise in forecasting, planning, IRT configuration, and end-to-end clinical supply chain optimization through his work on hundreds of trials on multiple indications.

Antoine Remiot

Article

Forecasting and optimization in clinical trials

Learn about the latest advances in clinical trial forecasting and optimization. Understand how technology can help you overcome challenges you face in your clinical trial supply management.

Read nowSolution

Professional Services

Optimization services for the clinical trial supply chain.

Our team of experts in clinical supply and manufacturing optimization helps pharma companies make better strategic decisions, mitigate risks, manage crisis situations and optimize processes.

Discover more

Article

What is clinical trial supply optimization?

Clinical trial supply optimization is the process of supplying the right amount of investigational medicinal product (IMP) and comparators to all trial sites so all patients receive their doses on schedule. Learn more it and how it can benefit you in this article.

Read now